ভাসমান ফোম ফ্যান্ডার উচ্চ শক্তি শোষণ দুর্দান্ত প্রভাব প্রতিরোধের অনিবার্য কাঠামো

বর্ণনা

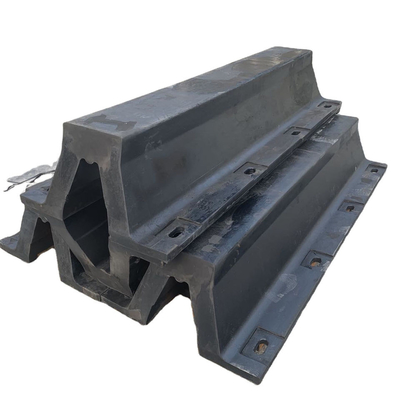

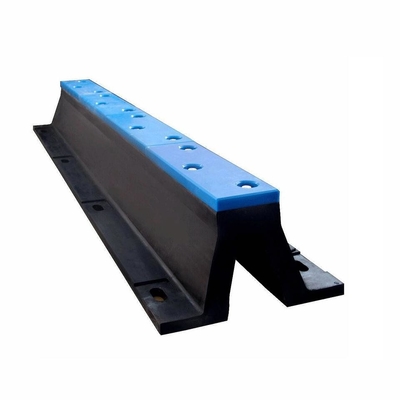

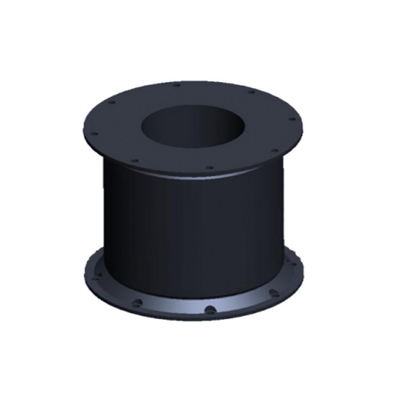

ফ্লোটিং ফোম ফ্যান্ডার একটি উচ্চ-পারফরম্যান্স সামুদ্রিক সুরক্ষা সমাধান যা বন্দর, শিপইয়ার্ড এবং অফশোর পরিবেশের জন্য ডিজাইন করা হয়েছে।এটি একটি বন্ধ কোষের পলিথিলিন ফেনা কোরকে একটি শক্তিশালী ইলাস্টোমার বা পলিউরেথেন বাইরের ত্বকের সাথে একত্রিত করে, যা বায়ু ফুটো হওয়ার ঝুঁকি ছাড়াই নির্ভরযোগ্য শক্তি শোষণ, কাঠামোগত স্থিতিস্থাপকতা এবং দীর্ঘমেয়াদী স্থায়িত্ব সরবরাহ করে।

ফ্যান্ডারটি পুনরাবৃত্তি উচ্চ লোডের অধীনে স্থিতিশীল কর্মক্ষমতা প্রদানের জন্য ডিজাইন করা হয়েছে। এর ফোম কোর দীর্ঘস্থায়ী সংকোচনের পরেও ধ্রুবক প্রতিক্রিয়া শক্তি এবং শক্তি শোষণ সরবরাহ করে,যদিও বাইরের প্রতিরক্ষামূলক স্তর ঘর্ষণের জন্য চমৎকার প্রতিরোধের নিশ্চিত করে, সমুদ্রের জল, ইউভি বিকিরণ, এবং কঠোর আবহাওয়া পরিস্থিতিতে। বায়ুসংক্রান্ত fenders বিপরীতে ভাসমান ফোম fender কোন inflation বা চাপ পর্যবেক্ষণ প্রয়োজন,অপারেটিং ঝুঁকি এবং রক্ষণাবেক্ষণ খরচ উল্লেখযোগ্যভাবে হ্রাস.

বিভিন্ন ব্যাসার্ধ এবং দৈর্ঘ্যের মধ্যে পাওয়া যায়, ফ্লোটিং ফোম ফ্যান্ডার নির্দিষ্ট জাহাজের আকার, মোরগিং শক্তি এবং ইনস্টলেশন অবস্থার সাথে মেলে।অপশনাল ফিটিং যেমন চেইন, ফ্ল্যাঞ্জ বা মাউন্টিং ব্র্যাকেটগুলি কয়েন দেয়াল, ডলফিন বা ভাসমান কাঠামোর মধ্যে নমনীয় সংহতকরণের অনুমতি দেয়।

একটি কার্যকরী দৃষ্টিকোণ থেকে, পণ্যটি জাহাজ এবং বন্দর অবকাঠামো উভয়ই রক্ষা করার জন্য ডিজাইন করা হয়েছে।এবং সামগ্রিক ডকিং নিরাপত্তা উন্নতএটির অজানা নকশা বাইরের ত্বকের ক্ষতির ক্ষেত্রেও অবিচ্ছিন্ন সুরক্ষা নিশ্চিত করে, এটিকে সমুদ্রের অপারেশনগুলির জন্য একটি নির্ভরযোগ্য সমাধান করে তোলে।

কেস স্টাডি ✓ কনটেইনার টার্মিনালের মর্টিং আপগ্রেড

দক্ষিণ-পূর্ব এশিয়ার একটি কনটেইনার টার্মিনালে 30,000 ₹ 50,000 ডাব্লুডব্লিউটি কনটেইনার জাহাজগুলি পুরানো রাবার ফ্যান্ডারগুলির কারণে ঘন ঘন কয়েন ক্ষতিগ্রস্থ হয়েছিল।৫ মিটার লং লিংক বরাবর স্থাপন করা হয়.

ইনস্টলেশনের পর, জাহাজের সমতল প্রভাব 40% এরও বেশি হ্রাস পেয়েছে, রক্ষণাবেক্ষণের সময় উল্লেখযোগ্যভাবে হ্রাস পেয়েছে এবং অপারেটররা জোয়ারের পরিবর্তনের মধ্যেও মসৃণ ডকিংয়ের প্রতিবেদন করেছে।টার্মিনাল অপারেটরদের কাছ থেকে ইতিবাচক প্রতিক্রিয়া পাওয়ার পর এই সমাধানটি তিনটি অতিরিক্ত বার্ডে পুনরাবৃত্তি করা হয়েছে.

বিশেষ উল্লেখ

| পণ্যের নাম |

ভাসমান ফোম ফ্যান্ডার |

| পণ্যের ধরন |

ক্লোজড সেল ফোম ভরা ফ্লোটিং ফেন্ডার |

| মূল উপাদান |

উচ্চ ঘনত্বের ক্লোজড সেল পলিথিলিন ফোম |

| বাহ্যিক ত্বক |

শক্তিশালী পলিউরেথেন বা ইলাস্টোমেরিক কাঁচ |

| ভাস্বরতা |

নিমজ্জনহীন, ইতিবাচক ভাসমানতা |

| শক্তি শোষণ |

নিম্ন প্রতিক্রিয়া শক্তির সাথে উচ্চ শক্তি শোষণ |

| আবহাওয়ার প্রতিরোধ ক্ষমতা |

ইউভি, সমুদ্রের জল, এবং বয়সের প্রতিরোধী |

| ইনস্টলেশন |

চেইন বা ব্র্যাকেট মাউন্ট, কাস্টমাইজযোগ্য |

| সেবা জীবন |

১৫-২০ বছর স্বাভাবিক অপারেটিং শর্তে |

|

ব্যাস x দৈর্ঘ্য

|

60% কমপক্ষে শক্তি শোষণ

|

প্রতিক্রিয়া শক্তি 60% comp

|

আনুমানিক ওজন

|

|

(মিমি)

|

(কেএনএম)

|

(কেএন)

|

(কেজি)

|

|

৩০০ x ১০০০

|

3.8

|

54

|

11

|

|

৫০০ x ১০০০

|

10.6

|

91

|

41

|

|

৬০০ x ১০০০

|

15.3

|

109

|

49

|

|

৬০০ x ১০০০

|

18.3

|

131

|

55

|

|

৭০০ x ১৫০০

|

31

|

191

|

85

|

|

৭৫০ x ১৫০০

|

36

|

204

|

89

|

|

৯০০ x ১৮০০

|

62

|

294

|

140

|

|

1000 x 1500

|

64

|

272

|

125

|

|

1000 x 2000

|

85

|

363

|

170

|

|

১২০০ x ২০০০

|

122

|

436

|

275

|

|

১২০০ x ২৪০০

|

146

|

523

|

365

|

|

১২৫০ x ২০০০

|

132

|

454

|

353

|

|

১২৫০ x ২৫০০

|

165

|

567

|

410

|

|

১৫০০ x ৩০০০

|

286

|

817

|

570

|

|

১৫০০ x ৪০০০

|

381

|

1089

|

720

|

|

১৭০০ x ৩০০০

|

367

|

926

|

700

|

|

১৭০০ x ৩৫০০

|

428

|

1080

|

780

|

|

১৮০০ x ৩০০০

|

412

|

980

|

850

|

|

১৮০০ x ৩৬০০

|

494

|

1176

|

965

|

|

২০০০ x ৩০০০

|

508

|

1089

|

965

|

|

২০০০ x ৩৫০০

|

593

|

1271

|

1100

|

|

২০০০ x ৪০০০

|

678

|

1452

|

1220

|

|

2400 x 4000

|

976

|

1743

|

1720

|

|

2400 x 4800

|

1171

|

2091

|

2140

|

|

2500 x 4000

|

1059

|

1815

|

1865

|

|

2500 x 5000

|

1324

|

2269

|

2500

|

|

2500 x 5500

|

1456

|

2496

|

2675

|

|

২৭০০ x ৫৪০০

|

1668

|

2647

|

2865

|

|

৩০০০ x ৫০০০

|

1925

|

2750

|

3200

|

|

৩০০০ x ৬০০০

|

2287

|

3268

|

3740

|

|

৩৩০০ x ৬৫০০

|

2998

|

3894

|

4735

|

|

3600 x 7200

|

3953

|

4706

|

5800

|

|

৪০০০ x ৮০০০

|

4522

|

5809

|

8700

|

|

৪২০০ x ৮৪০০

|

6277

|

6405

|

10000

|

|

৪৫০০ x ৯০০০

|

7720

|

7353

|

10700

|

বৈশিষ্ট্য

উচ্চ শক্তি শোষণ ক্ষমতা

ফোম কোরটি প্রভাবের শক্তিকে অভিন্নভাবে বিতরণ করে, জাহাজের খাঁজ এবং কয়ে দেয়ালগুলিতে শিখর চাপ হ্রাস করে।এই নকশা অত্যধিক প্রতিক্রিয়া শক্তি ছাড়া বড় স্থানচ্যুতি জাহাজের জন্য নিরাপদ anchoring সক্ষম.

ঘর্ষণ এবং ইউভি প্রতিরোধী বাইরের ত্বক

শক্তিশালী ইলাস্টোমেরিক লেপটি পুনরাবৃত্তি পরিবেশে ঘর্ষণ প্রতিরোধ করে এবং দীর্ঘস্থায়ী ইউভি এক্সপোজারে কাঠামোগত অখণ্ডতা বজায় রাখে,গ্রীষ্মমন্ডলীয় এবং অফশোর পরিবেশে দীর্ঘ সেবা জীবন নিশ্চিত করা.

ডুবে না যাওয়া এবং রক্ষণাবেক্ষণ-মুক্ত নকশা

এমনকি যদি বাইরের ত্বকটি ক্ষতিগ্রস্ত হয়, তবে বন্ধ কোষের ফোয়ারা জল প্রবেশের প্রতিরোধ করে, ডুবে যাওয়ার ঝুঁকি দূর করে এবং inflatable সিস্টেমের তুলনায় রক্ষণাবেক্ষণের প্রয়োজনীয়তা হ্রাস করে।

জোয়ার পরিস্থিতিতে স্থিতিশীল পারফরম্যান্স

ভাসমান নকশাটি ফ্যান্ডারকে স্বয়ংক্রিয়ভাবে জলের স্তরের পরিবর্তনের সাথে সামঞ্জস্য করতে দেয়, বিভিন্ন জোয়ারের পরিসরে কার্যকর সুরক্ষা বজায় রাখে।

অ্যাপ্লিকেশন

বাণিজ্যিক বন্দর এবং কনটেইনার টার্মিনাল

কনটেইনার জাহাজ, বাল্ক ক্যারিয়ার এবং সাধারণ কার্গো জাহাজের ঘন ঘন মেরামত করার জন্য ডিজাইন করা।

জাহাজঘাঁটি ও মেরামতের ডক

জাহাজের রক্ষণাবেক্ষণ, পুনরায় সজ্জিত এবং শুকনো ডকের প্রবেশের ক্রিয়াকলাপের সময় জাহাজের দেহ সুরক্ষা প্রদান করে।

অফশোর মার্চিং এবং ভাসমান কাঠামো

ভাসমান পন্টোন, অফশোর প্ল্যাটফর্ম এবং সাময়িক সামুদ্রিক সুবিধা জন্য উপযুক্ত।

কেন হংক্রুন্টং মেরিন বেছে নিন

প্রমাণিত ইঞ্জিনিয়ারিং দক্ষতা

হংক্রুন্টং মেরিনের সামুদ্রিক ফেন্ডার ডিজাইনে ব্যাপক অভিজ্ঞতা রয়েছে, বাস্তব বিশ্বের অপারেশনাল চ্যালেঞ্জগুলির জন্য উপযুক্ত সমাধান সরবরাহ করে।

কাস্টম ডিজাইন ক্ষমতা

আমরা জাহাজের ধরন, লেজ কাঠামো, এবং শক্তির চাহিদার উপর ভিত্তি করে কাস্টমাইজড ফেন্ডার মাত্রা, ত্বকের উপকরণ, এবং সংযুক্তি সিস্টেম প্রদান করি।

উচ্চমানের উপাদান নির্বাচন

কেবলমাত্র সামুদ্রিক গ্রেডের ফোম এবং সার্টিফাইড ইলাস্টোমারিক লেপ ব্যবহার করা হয় যা স্থায়িত্ব, নিরাপত্তা এবং আন্তর্জাতিক মানের সাথে সম্মতি নিশ্চিত করে।

বিক্রয়োত্তর ব্যাপক সহায়তা

ইনস্টলেশন গাইডেন্স থেকে শুরু করে দীর্ঘমেয়াদী পারফরম্যান্স মূল্যায়ন পর্যন্ত, আমাদের প্রযুক্তিগত দল পণ্যের জীবনচক্র জুড়ে গ্রাহকদের সহায়তা করে।

প্রায়শই জিজ্ঞাসিত প্রশ্ন

1. ফ্লোটিং ফোম ফেনডারের জন্য কোন আকার পাওয়া যায়?

স্ট্যান্ডার্ড ব্যাসার্ধ 500 মিমি থেকে 4,500 মিমি পর্যন্ত, অনুরোধে কাস্টম দৈর্ঘ্য উপলব্ধ।

2এই ফ্যান্ডারটি কি চরম তাপমাত্রায় ব্যবহার করা যায়?

হ্যাঁ, এই উপকরণগুলি -৪০° সেলসিয়াস থেকে +৮০° সেলসিয়াস তাপমাত্রায় নির্ভরযোগ্যভাবে কাজ করার জন্য ডিজাইন করা হয়েছে।

3সার্টিফিকেশন আছে?

পণ্যগুলি অনুরোধের ভিত্তিতে তৃতীয় পক্ষের পরিদর্শন শংসাপত্রের সাথে সরবরাহ করা যেতে পারে যেমন সিসিএস, বিভি, বা ডিএনভি।

4ফ্যান্টার কিভাবে ইনস্টল করা হয়?

সাইটের অবস্থার উপর নির্ভর করে চেইন, ব্র্যাকেট বা ভাসমান সিস্টেমের মাধ্যমে ইনস্টলেশন করা যেতে পারে।

5. প্রত্যাশিত সেবা জীবন কি?

সঠিকভাবে নির্বাচন করলে, পরিষেবা জীবন সাধারণত 15 থেকে 20 বছর অতিক্রম করে।

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!  আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!