ডি টাইপ ফেন্ডার টেকসই নির্মাণ উচ্চ প্রভাব প্রতিরোধের জাহাজগুলিতে সহজ স্থাপন

বর্ণনা

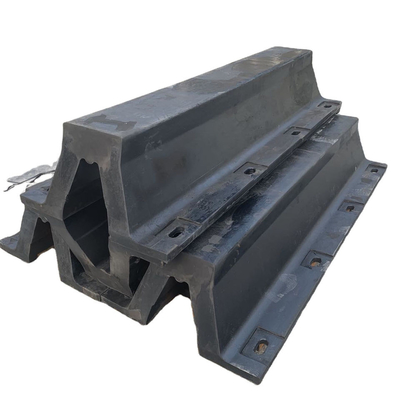

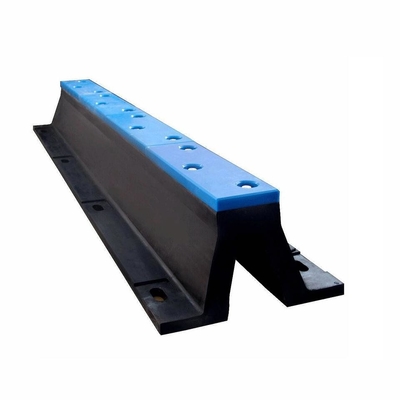

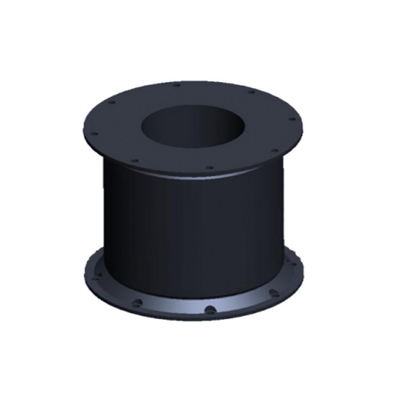

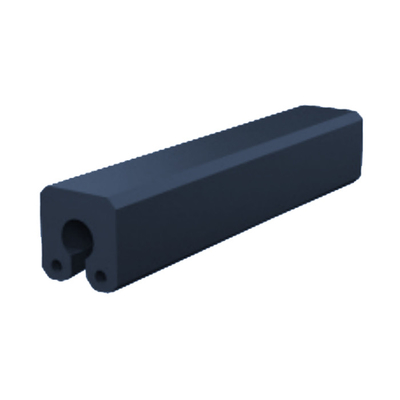

ডি টাইপ ফেন্ডার হল একটি বহুমুখী এবং অত্যন্ত নির্ভরযোগ্য মেরিন ফেন্ডার সিস্টেম যা জাহাজ এবং কুই কাঠামোর মধ্যে প্রভাব শক্তি শোষণ করার জন্য ডিজাইন করা হয়েছে। এর আধা-বৃত্তাকার “D” আকৃতি নমনীয়তা এবং শক্তি শোষণের একটি সর্বোত্তম সমন্বয় প্রদান করে, যা ছোট থেকে মাঝারি আকারের জাহাজ, টাগবোট এবং ওয়ার্কিং বোটের জন্য উপযুক্ত করে তোলে। প্রিমিয়াম মেরিন-গ্রেড রাবার দিয়ে তৈরি, ডি টাইপ ফেন্ডার ওজোন, লবণাক্ত জল, UV এক্সপোজার এবং যান্ত্রিক চাপের বিরুদ্ধে চমৎকার প্রতিরোধ ক্ষমতা প্রদান করে। এর ফাঁপা অভ্যন্তরীণ চেম্বার চাপের মধ্যে উল্লেখযোগ্যdeflection-এর অনুমতি দেয়, যা কার্যকরভাবে সংঘর্ষের শক্তি হ্রাস করে এবং জাহাজ এবং ডক উভয় পৃষ্ঠকে রক্ষা করে।

ফেন্ডারের কমপ্যাক্ট প্রোফাইল এটিকে স্ট্যান্ডার্ড বোল্ট বা চেইন সিস্টেম ব্যবহার করে কুই ওয়াল, টাগবোট এবং পন্টুন প্রান্তে সহজে মাউন্ট করার অনুমতি দেয়। এক্সট্রুশন উত্পাদন প্রক্রিয়া ধারাবাহিক প্রাচীর বেধ এবং অভিন্ন ভৌত বৈশিষ্ট্য নিশ্চিত করে, যা কঠোর সমুদ্র পরিবেশে কর্মক্ষমতা নির্ভরযোগ্যতার নিশ্চয়তা দেয়।

কেস স্টাডি – রটারডাম বন্দর, নেদারল্যান্ডস

রটারডাম বন্দরে পরিচালিত একটি মাঝারি আকারের টাগ বহর কংক্রিট কুইগুলির সাথে ঘন ঘন যোগাযোগের কারণে বার্থিং অপারেশনের সময় হুলের প্রান্তে বারবার ক্ষতির সম্মুখীন হয়েছিল। ঐতিহ্যবাহী বর্গাকার ফেন্ডারগুলি উচ্চ দৃঢ়তা প্রদান করে কিন্তু কম শক্তি শোষণ করে, যার ফলে অতিরিক্ত প্রভাবের চাপ হয়। হংরুনটং মেরিনকে ঘর্ষণ-প্রতিরোধী প্রাকৃতিক এবং সিন্থেটিক রাবার মিশ্রণ থেকে তৈরি কাস্টম ডি টাইপ ফেন্ডার দিয়ে পুরানো সিস্টেমটি প্রতিস্থাপনের জন্য কমিশন করা হয়েছিল।

ইনস্টলেশনের পরে, ফিল্ড পরিমাপ দেখায় ডকিংয়ের সময় হুলের বিকৃতিতে 35% হ্রাস এবং প্রচলিত রাবার ব্লকের তুলনায় শক্তি শোষণ দক্ষতায় 50% বৃদ্ধি। ফেন্ডার প্রতিস্থাপনের রক্ষণাবেক্ষণ ব্যবধান 18 মাস থেকে 5 বছরের বেশি পর্যন্ত বাড়ানো হয়েছে। ক্লায়েন্ট বার্থিং সারিবদ্ধকরণ এবং মসৃণ জাহাজের ক্রিয়াকলাপের উন্নতিও জানিয়েছে, বিশেষ করে জোয়ারের পরিবর্তনের অধীনে। এই প্রকল্পটি কঠিন হারবার পরিস্থিতিতে হংরুনটং-এর ডি টাইপ ফেন্ডারের স্থায়িত্ব এবং ব্যয়-কার্যকারিতা প্রদর্শন করেছে।

স্পেসিফিকেশন

| পণ্যের নাম |

ডি টাইপ ফেন্ডার |

| ব্র্যান্ড নাম |

হংরুনটং মেরিন |

| উপাদান |

উচ্চ পারফরম্যান্স প্রাকৃতিক রাবার |

| রঙ |

কালো এবং গ্রাহকদের প্রয়োজনীয়তা |

| প্রকার |

ফিক্সড ডি রাবার ফেন্ডার |

| স্ট্যান্ডার্ড |

HGT2866-2016, PIANC2002 |

| শক্তি শোষণ |

147kN থেকে 920kN |

| প্রতিক্রিয়া শক্তি |

5.1KN-M থেকে 64KN-M |

| অ্যাপ্লিকেশন |

বন্দর, ডক, কুই, ইত্যাদি |

| A |

B |

C |

D |

E |

F |

H |

K |

| [মিমি] |

[মিমি] |

[মিমি] |

[মিমি] |

[মিমি] |

[মিমি] |

[মিমি] |

[মিমি] |

| 70 |

30 |

15 |

30 |

45 |

80 |

90 - 130 |

200 - 300 |

| 100 |

45 |

15 |

30 |

50 |

100 |

90 - 130 |

200 - 300 |

| 125 |

60 |

20 |

40 |

60 |

125 |

110 - 150 |

250 - 300 |

| 150 |

75 |

20 |

40 |

75 |

150 |

110 - 150 |

250 - 300 |

| 150 |

80 |

25 |

50 |

100 |

200 |

130 - 180 |

300 - 400 |

| 200 |

100 |

25 |

50 |

100 |

200 |

130 - 180 |

300 - 400 |

| 200 |

100 |

30 |

60 |

125 |

250 |

140 - 200 |

350 - 450 |

| 250 |

125 |

30 |

60 |

125 |

250 |

140 - 200 |

350 - 450 |

| 300 |

150 |

30 |

60 |

150 |

300 |

140 - 200 |

350 - 450 |

| 350 |

175 |

35 |

75 |

175 |

350 |

140 - 200 |

350 - 450 |

| 380 |

190 |

35 |

75 |

190 |

380 |

140 - 200 |

350 - 450 |

| 300 |

150 |

35 |

75 |

175 |

400 |

140 - 200 |

350 - 450 |

| 400 |

200 |

35 |

75 |

200 |

400 |

140 - 200 |

350 - 450 |

| 500 |

250 |

45 |

90 |

250 |

500 |

160 - 230 |

400 - 500 |

| *দ্রষ্টব্য: অন্যান্য আকার প্রয়োজনীয়তা অনুযায়ী কাস্টমাইজ করা যেতে পারে। |

| A |

B |

C |

D |

E |

F |

G |

H |

K |

| [মিমি] |

[মিমি] |

[মিমি] |

[মিমি] |

[মিমি] |

[মিমি] |

[মিমি] |

[মিমি] |

[মিমি] |

| 100 |

25 |

10 |

30 |

15 |

100 |

50 |

90 - 130 |

200 - 300 |

| 150 |

30 |

12 |

65 |

20 |

150 |

75 |

110 - 150 |

250 - 350 |

| 200 |

45 |

15 |

75 |

25 |

200 |

100 |

130 - 180 |

300 - 400 |

| 250 |

50 |

20 |

100 |

30 |

250 |

125 |

140 - 200 |

350 - 450 |

| 300 |

60 |

25 |

125 |

30 |

300 |

150 |

140 - 200 |

350 - 450 |

| 350 |

70 |

25 |

150 |

35 |

350 |

175 |

140 - 200 |

350 - 450 |

| 400 |

80 |

30 |

175 |

35 |

400 |

200 |

140 - 200 |

350 - 450 |

| 400 |

80 |

30 |

200 |

35 |

400 |

200 |

140 - 200 |

350 - 450 |

| 500 |

100 |

30 |

250 |

35 |

500 |

250 |

140 - 200 |

350 - 450 |

বৈশিষ্ট্য

কম প্রতিক্রিয়া শক্তির সাথে উচ্চ শক্তি শোষণ

ফেন্ডারের অভ্যন্তরীণ ফাঁপা কোর কাঠামো সুপিরিয়র ডিফ্লেকশন-এর জন্য অনুমতি দেয়, যা যোগাযোগের পৃষ্ঠের উপর সমানভাবে প্রভাব শক্তি বিতরণ করে। ঐতিহ্যবাহী বর্গাকার বা নলাকার ফেন্ডারের সাথে তুলনা করে, ডি টাইপ ফেন্ডারগুলি একটি ভাল শক্তি-থেকে-প্রতিক্রিয়া অনুপাত সরবরাহ করে, যা ডক এবং জাহাজ উভয়ের জন্য দক্ষ সুরক্ষা নিশ্চিত করে।

চমৎকার আবহাওয়া এবং সমুদ্রের জলের প্রতিরোধ ক্ষমতা

যৌগিক ফর্মুলেশনে অ্যান্টি-ওজোনেন্ট এবং UV স্টেবিলাইজার অন্তর্ভুক্ত রয়েছে, যা সমুদ্রের পরিস্থিতিতে দীর্ঘ সময় ধরে স্থিতিস্থাপকতা এবং কর্মক্ষমতা বজায় রাখে। এটি পৃষ্ঠের ফাটল এবং উপাদান হ্রাস কমিয়ে দেয়, দীর্ঘমেয়াদী নির্ভরযোগ্যতা নিশ্চিত করে।

নমনীয় মাউন্টিং এবং অভিযোজনযোগ্যতা

ফ্ল্যাট পিছনের পৃষ্ঠটি বোল্ট, চেইন বা এমবেডেড স্টিল স্ট্রিপ ব্যবহার করে ফ্ল্যাট বা বাঁকা হুলে সহজে ইনস্টলেশনের অনুমতি দেয়। হংরুনটং নির্দিষ্ট কাঠামোগত প্রয়োজনীয়তার জন্য কাস্টম দৈর্ঘ্য, প্রি-ড্রিল করা কনফিগারেশন বা অবিচ্ছিন্ন এক্সট্রুশনে ফেন্ডার সরবরাহ করতে পারে।

কম রক্ষণাবেক্ষণ এবং দীর্ঘ পরিষেবা জীবন

দীর্ঘায়িত কার্যকরী জীবনের জন্য ডিজাইন করা হয়েছে, ডি টাইপ ফেন্ডারের ন্যূনতম রক্ষণাবেক্ষণের প্রয়োজন। সর্বোত্তম কার্যকারিতা বজায় রাখতে নিয়মিত পরিষ্কার এবং পরিদর্শন যথেষ্ট। অনেক ইনস্টলেশন প্রধান সংস্কার ছাড়াই 10 বছরের বেশি সময় ধরে সম্পূর্ণরূপে কার্যকরী রয়েছে।

অ্যাপ্লিকেশন

হারবার এবং জেটি কাঠামো

বার্থিং এবং মুরিংয়ের সময় জাহাজের প্রভাব থেকে কুই ওয়াল এবং জেটি প্রান্তগুলিকে রক্ষা করে, দীর্ঘমেয়াদী কাঠামোগত নিরাপত্তা প্রদান করে।

টাগবোট এবং ওয়ার্কবোট

টোয়িং বা ম্যানুভারিং অপারেশনের সময় সংঘর্ষের শক্তি শোষণ করতে হুলের পাশে বা বো-তে ইনস্টল করা হয়।

অভ্যন্তরীণ জলপথ এবং পন্টুন

নদী বন্দর, ভাসমান ডক এবং ফেরি টার্মিনালে মসৃণ ডকিং নিশ্চিত করে এবং হুলের ঘর্ষণ প্রতিরোধ করে।

কেন হংরুনটং মেরিন নির্বাচন করবেন

উন্নত উপাদান প্রকৌশল

হংরুনটং সর্বোত্তম প্রসার্য শক্তি, প্রসারণ এবং সংকোচন স্থিতিস্থাপকতা অর্জনের জন্য প্রাকৃতিক এবং সিন্থেটিক পলিমারগুলিকে একত্রিত করে একটি মালিকানাধীন রাবার কম্পাউন্ডিং প্রক্রিয়া ব্যবহার করে। প্রতিটি ব্যাচ কঠোরতা, টিয়ার রেজিস্ট্যান্স এবং বিকৃতি পুনরুদ্ধারের জন্য পরীক্ষা করা হয়।

নির্ভুল উত্পাদন প্রক্রিয়া

উচ্চ-ক্ষমতার এক্সট্রুশন এবং ভালকানাইজেশন সরঞ্জাম ব্যবহার করে, প্রতিটি ফেন্ডার অভিন্ন ঘনত্ব এবং প্রাচীর বেধ বজায় রাখে। মাত্রিক নির্ভুলতা প্রভাবের সময় নিখুঁত সারিবদ্ধকরণ এবং ধারাবাহিক ডিফ্লেকশন আচরণ নিশ্চিত করে।

গ্লোবাল প্রজেক্ট অভিজ্ঞতা

হংরুনটং মেরিন বিশ্বব্যাপী 60 টিরও বেশি বন্দরে ফেন্ডার সিস্টেম সরবরাহ করেছে, বিভিন্ন পরিবেশগত এবং লোড অবস্থার সাথে পণ্যগুলিকে মানিয়ে নিচ্ছে। প্রতিটি ইনস্টলেশনের পিছনে প্রযুক্তিগত অঙ্কন, মাউন্টিং হার্ডওয়্যার এবং সম্পূর্ণ বিক্রয়োত্তর পরিষেবা রয়েছে।

টেকসইতা এবং গুণমান নিশ্চিতকরণ

উৎপাদন ISO 9001 এবং ISO 14001 মান মেনে চলে। রাবার উপকরণ সম্পূর্ণরূপে পুনর্ব্যবহারযোগ্য, এবং উত্পাদন বর্জ্য হ্রাস করা হয়। সমস্ত পণ্য চালানের আগে 100% ভিজ্যুয়াল এবং মাত্রিক পরিদর্শন করা হয়।

FAQ

1. ডি টাইপ ফেন্ডারের জন্য কি আকার পাওয়া যায়?

স্ট্যান্ডার্ড আকারগুলি D100 থেকে D500 পর্যন্ত, কাস্টম দৈর্ঘ্য অনুরোধের ভিত্তিতে 20 মিটার পর্যন্ত পাওয়া যায়।

2. ডি টাইপ ফেন্ডার কিভাবে ইনস্টল করা হয়?

মাউন্টিং পৃষ্ঠ এবং জাহাজের ধরনের উপর নির্ভর করে বোল্ট, চেইন বা স্টিল স্ট্রিপের মাধ্যমে ইনস্টলেশন করা যেতে পারে।

3. ফেন্ডারগুলি কি অবিচ্ছিন্ন দৈর্ঘ্যে সরবরাহ করা যেতে পারে?

হ্যাঁ, 10 মিটার পর্যন্ত অবিচ্ছিন্ন এক্সট্রুশন তৈরি করা যেতে পারে, যা জয়েন্টগুলির প্রয়োজনীয়তা হ্রাস করে।

4. সাধারণ পরিষেবা জীবন কত?

সঠিক রক্ষণাবেক্ষণের সাথে, হংরুনটং ডি টাইপ ফেন্ডারগুলি ব্যবহারের অবস্থার উপর নির্ভর করে 8–15 বছর স্থায়ী হতে পারে।

5. উপলব্ধ রঙের বিকল্প আছে কি?

স্ট্যান্ডার্ড রঙ কালো, তবে UV-স্থিতিশীল রঙ্গক ব্যবহার করে ধূসর, নীল এবং কাস্টম রং সরবরাহ করা যেতে পারে।

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!  আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!