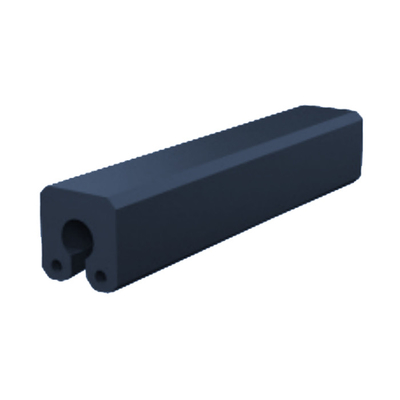

ডক হোস উচ্চ পরিধান প্রতিরোধের হালকা ওজন মসৃণ প্রবাহ বর্ধিত স্থায়িত্ব

বর্ণনা

এসটিএস হ'ল উচ্চ-পারফরম্যান্সের নমনীয় নল যা উচ্চ চাপের তরল স্থানান্তরের জন্য ডিজাইন করা হয়েছে। শক্তিশালী সিন্থেটিক উপকরণ দিয়ে নির্মিত,পটানো ইস্পাত বা টেক্সটাইল স্তর সহএই নলগুলি হাইড্রোলিক সিস্টেম, শিল্প যন্ত্রপাতি, অটোমোবাইল অ্যাপ্লিকেশন, নির্মাণ সরঞ্জাম,এবং সামুদ্রিক বা অফশোর অপারেশন.

ফাঁস-প্রমাণ অপারেশন, রাসায়নিক প্রতিরোধের, এবং তাপ স্থিতিশীলতার জন্য ডিজাইন করা, এসটিএস পায়ের পাতার মোজাবিশেষ চরম অবস্থার অধীনে ধারাবাহিক তরল সরবরাহ নিশ্চিত করে।তাদের শক্তিশালী নকশা যন্ত্রপাতি দক্ষতা সর্বাধিকীকরণের সময় ডাউনটাইম এবং রক্ষণাবেক্ষণ খরচ কমাতে.

কেস স্টাডিঃ হাইড্রোলিক প্রেস সিস্টেম

হাইড্রোলিক প্রেস মেশিনের একটি নির্মাতা তাদের উচ্চ চাপ সার্কিটগুলির জন্য এসটিএস পায়ের পাতার মোজাবিশেষে আপগ্রেড করেছে। পায়ের পাতার মোজাবিশেষগুলি ধ্রুবক চাপ বজায় রেখেছে এবং অবিচ্ছিন্ন অপারেশনের কারণে পরিধানের প্রতিরোধ করেছে। ফলস্বরূপ,নির্মাতার উৎপাদন দক্ষতা 25% বৃদ্ধি এবং রক্ষণাবেক্ষণের ব্যবধান উল্লেখযোগ্যভাবে হ্রাস পেয়েছে.

বিশেষ উল্লেখ

| উপাদান |

পিটিএফই, গ্যালভানাইজড স্টিলের তার, পিভিসি লেপা পলিস্টার কাপড় |

| পণ্যের নাম |

এসটিএস নল |

| আকার |

HM-SH78 |

| অভ্যন্তরীণ তারের |

স্টেইনলেস স্টীল ৩১৬ |

| আস্তরণ |

পলিয়ামাইড |

| শবদেহ |

পলিয়ামাইড কাপড়, পলিস্টার ফিল্ম |

| বাহ্যিক তার |

স্টেইনলেস স্টীল ৩১৬ |

| কাজের চাপ |

১০ বার থেকে ২১ বার |

| সর্বাধিক দৈর্ঘ্য |

৪০ মিটার |

| নমুনা |

উপলব্ধ |

| ডেলিভারি সময় |

সাধারণত ৩-৫ দিন |

| মডেল |

মাত্রা |

কাজের চাপ |

নিরাপত্তা ফ্যাক্টর |

বাঁকানো ব্যাসার্ধ |

ওজন |

দৈর্ঘ্য |

| কম্পোজিট |

[এমএম] |

[ইঞ্চি] |

[বার] |

[পিএসআই] |

[কেজি] |

[m] |

| HM-SH20 |

20 |

3/4 " |

16 |

230 |

6:1 |

80 |

0.8 |

40 |

| HM-SH25 |

25 |

১" |

16 |

230 |

6:1 |

100 |

1 |

40 |

| HM-SH32 |

32 |

১১/৪" |

16 |

230 |

6:1 |

125 |

1.3 |

40 |

| HM-SH40 |

40 |

১১/২" |

16 |

230 |

6:1 |

140 |

1.5 |

40 |

| HM-SH50 |

50 |

২" |

16 |

230 |

6:1 |

180 |

2.5 |

40 |

| HM-SH65 |

65 |

২১/২" |

16 |

230 |

6:1 |

200 |

3.3 |

40 |

| HM-SH80 |

80 |

৩" |

16 |

230 |

6:1 |

260 |

4 |

40 |

| HM-SH100 |

100 |

৪" |

16 |

230 |

6:1 |

380 |

6.8 |

40 |

| HM-SH125 |

125 |

৫" |

16 |

230 |

6:1 |

440 |

9.2 |

40 |

| HM-SH150 |

150 |

৬" |

16 |

230 |

6:1 |

500 |

13.2 |

40 |

| HM-SH200 |

200 |

৮" |

16 |

230 |

6:1 |

750 |

18 |

40 |

| HM-SH250 |

250 |

১০" |

16 |

230 |

6:1 |

900 |

26 |

25 |

| * দ্রষ্টব্যঃ প্রয়োজনীয়তা অনুযায়ী বিভিন্ন আকার কাস্টমাইজ করা যেতে পারে। |

বৈশিষ্ট্য

ব্যতিক্রমী চাপ প্রতিরোধ ক্ষমতা

STS পায়ের পাতার মোজাবিশেষ অত্যন্ত হাইড্রোলিক চাপ মোকাবেলা করার জন্য শক্তিশালী করা হয়, উচ্চ চাহিদা অ্যাপ্লিকেশন নির্ভরযোগ্য এবং নিরাপদ তরল স্থানান্তর নিশ্চিত। তাদের অভ্যন্তরীণ নির্মাণ ফুটো, ফাটল,এবং চাপ কমে যায়.

উচ্চতর নমনীয়তা এবং সহজ ইনস্টলেশন

তাদের চাপ ক্ষমতা সত্ত্বেও, এসটিএস পায়ের পাতার মোজাবিশেষগুলি অত্যন্ত নমনীয় থাকে, যা টাইট বা জটিল মেশিন কনফিগারেশনে ইনস্টলেশনকে অনুমতি দেয়।হালকা ওজনের নকশা সংযোগকারীগুলির উপর চাপ কমিয়ে দেয় এবং সামগ্রিক সিস্টেমের দক্ষতা উন্নত করে.

ঘর্ষণ এবং পরিবেশগত ক্ষতির বিরুদ্ধে স্থায়িত্ব

এসটিএস পায়ের পাতার মোজাবিশেষগুলির বাইরের স্তরটি কাটা, ক্ষয় এবং যান্ত্রিক প্রভাবের প্রতিরোধী। এটি কঠোর শিল্প, নির্মাণ বা সামুদ্রিক পরিবেশে দীর্ঘমেয়াদী স্থায়িত্ব নিশ্চিত করে।

রাসায়নিক, তেল, এবং তাপমাত্রার প্রতিরোধ ক্ষমতা

এসটিএস পায়ের পাতাগুলি বিভিন্ন হাইড্রোলিক তরল, জ্বালানী এবং রাসায়নিকের সাথে সামঞ্জস্যপূর্ণ, চরম তাপমাত্রায় কর্মক্ষমতা বজায় রাখে। তারা তাপীয় সম্প্রসারণ, ফাটল এবং উপাদান অবক্ষয় প্রতিরোধী,দীর্ঘমেয়াদী নির্ভরযোগ্যতা নিশ্চিত করা.

প্রয়োগ

রাসায়নিক পণ্য পরিবহন

এসটিএস পায়ের পাতার মোজাবিশেষগুলি রাসায়নিক ট্যাঙ্কার এবং উপকূলীয় ট্যাঙ্কারগুলির মধ্যে বাল্ক পরিবহনে অ্যাসিড, আলকালি এবং দ্রাবকগুলির মতো আক্রমণাত্মক রাসায়নিকগুলি পরিচালনা করে।তাদের অভ্যন্তরীণ আবরণ রাসায়নিক সামঞ্জস্য এবং জারা প্রতিরোধের জন্য ডিজাইন করা হয়.

বাঙ্কারিং এবং মেরিন ফুয়েলিং

সামুদ্রিক বঙ্কারিং অপারেশনের সময় ব্যবহৃত, এসটিএস পায়ের পাতাগুলি ভারী জ্বালানী তেল (এইচএফও), সামুদ্রিক ডিজেল তেল (এমডিও) এবং সামুদ্রিক গ্যাস তেল (এমজিও) অ্যাঙ্কর বা লঙ্গরে জাহাজে স্থানান্তর করে।তারা উচ্চ চাপের অবস্থার অধীনে নিরাপদ জ্বালানী সরবরাহের জন্য ডিজাইন করা হয়.

পানীয় এবং মিষ্টি পানির সরবরাহ

অফশোর সরবরাহ অপারেশনগুলিতে, এসটিএস পায়ের পাতাগুলি সরবরাহকারী জাহাজ থেকে অফশোর প্ল্যাটফর্ম, জাহাজ বা দূরবর্তী স্থানে মিষ্টি জল বা পানীয় জল স্থানান্তর করতে ব্যবহৃত হয়।তারা পানীয় জলের নিরাপত্তার জন্য অনুমোদিত উপকরণ দিয়ে আবৃত.

কেন আমাদের কোম্পানি বেছে নিন

উচ্চমানের উপাদান

আমরা উচ্চমানের সিন্থেটিক উপকরণ এবং ইস্পাত বা টেক্সটাইল শক্তিশালীকরণ ব্যবহার করি যা নিরাপত্তা এবং নির্ভরযোগ্যতার জন্য আন্তর্জাতিক মান পূরণ করে।

ব্যক্তিগতকৃত সমাধান

আমাদের নলগুলি দৈর্ঘ্য, ব্যাসার্ধ, চাপ রেটিং এবং উপাদান রচনাতে কাস্টমাইজযোগ্য, যা ক্লায়েন্টদের নির্দিষ্ট অপারেশনাল প্রয়োজনীয়তা পূরণ করতে দেয়।

বিশেষজ্ঞ প্রযুক্তিগত সহায়তা

আমাদের টিম নির্বাচন, ইনস্টলেশন এবং রক্ষণাবেক্ষণ সম্পর্কে গাইডেন্স প্রদান করে। গ্রাহকরা সর্বাধিক পায়ের পাতার মোজাবিশেষ জীবনকাল এবং সিস্টেম কর্মক্ষমতা জন্য চলমান সমর্থন পান।

প্রমাণিত নির্ভরযোগ্যতা এবং বিশ্বব্যাপী স্বীকৃতি

ব্যাপক অভিজ্ঞতা এবং একটি বিশ্বব্যাপী ক্লায়েন্ট বেস সঙ্গে, আমাদের STS পায়ের পাতার মোজাবিশেষ শিল্প, স্বয়ংচালিত, নির্মাণ, এবং সামুদ্রিক সেক্টর জুড়ে কর্মক্ষমতা প্রমাণিত হয়েছে,আমাদের পণ্যগুলির প্রতি আস্থা এবং বিশ্বাস নিশ্চিত করা.

প্রায়শই জিজ্ঞাসিত প্রশ্ন

প্রশ্ন 1: এসটিএস পায়ের পাতার মোজাবিশেষগুলির সাধারণ কাজের চাপের পরিসীমা কী?

A1: মডেল এবং শক্তিশালীকরণের ধরন উপর নির্ভর করে, STS পায়ের পাতার মোজাবিশেষ 2000 PSI থেকে 6000 PSI এর উপরে চাপ পরিচালনা করে, বেশিরভাগ শিল্প এবং জলবাহী অ্যাপ্লিকেশনগুলির জন্য উপযুক্ত।

প্রশ্ন ২ঃ এসটিএস পায়ের পাতাগুলি কি চরম তাপমাত্রার অবস্থার মধ্যে কাজ করতে পারে?

উত্তরঃ হ্যাঁ, এসটিএস পায়ের পাতার মোজাবিশেষগুলি -40 °C থেকে +125 °C পর্যন্ত তাপমাত্রায় নির্ভরযোগ্যভাবে কাজ করে, নমনীয়তা এবং অখণ্ডতা বজায় রাখে।

প্রশ্ন 3: এসটিএস পায়ের পাতার মোজাবিশেষগুলি তেল এবং রাসায়নিকের প্রতিরোধী?

উত্তরঃ হ্যাঁ, তারা হাইড্রোলিক তরল, তেল, জ্বালানী এবং বিভিন্ন শিল্প রাসায়নিকের সাথে সামঞ্জস্যপূর্ণ, অবনতি বা ফুটো হওয়ার ঝুঁকি হ্রাস করে।

প্রশ্ন ৪ঃ এসটিএস পায়ের পাতার মোজাবিশেষ সাধারণত কতদিন স্থায়ী হয়?

A4: পরিবেশ এবং ব্যবহারের উপর নির্ভর করে পরিষেবা জীবন পরিবর্তিত হয়, তবে তাদের উচ্চতর ঘর্ষণ এবং রাসায়নিক প্রতিরোধের অপারেশনাল জীবনকালকে উল্লেখযোগ্যভাবে বাড়িয়ে তোলে,প্রায়শই বেশ কয়েক বছর স্থায়ী হয় সাধারণ শিল্প ব্যবহারের অধীনে.

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!  আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে!

আপনার বার্তাটি 20-3,000 টির মধ্যে হতে হবে! অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!

অনুগ্রহপূর্বক আপনার ইমেইল চেক করুন!